The Combo press 630-00-150-BR gives you the best of 2 techniques, both hot vulcanizing and infrared splicing. This make the combo press a flexible and perfect if you need to splice both rubber and plastic profiles. Switching between the 2 techniques is done simply by one click in the touch display.

The press is equipped with infrared heating elements heating the end of the profiles and practically melts the plastic profiles together. This makes the splice as fine as a rubber splice.

THE MOST ADVANCED SPLICING PRESS IN THE MARKED:

- All features are controlled in the touch-display.

- Superior heat control.

MORE EFFECTIVE THEN EVER:

- Automatic pre-heating of the machine.

- Automatic calibrating of heating elements.

100% CONTROL OVER THE PRODUCTION:

- 1 year production log.

- Up to 5 security levels.

- Receipt menu for up to 100 different profiles.

MOULD:

- Fast mould change.

- Minimum mould wear.

- Up to 175 mm mould.

TROUBLESHOOTING:

- Troubleshooting directly in the Interface.

- Possible for troubleshooting by LAN.

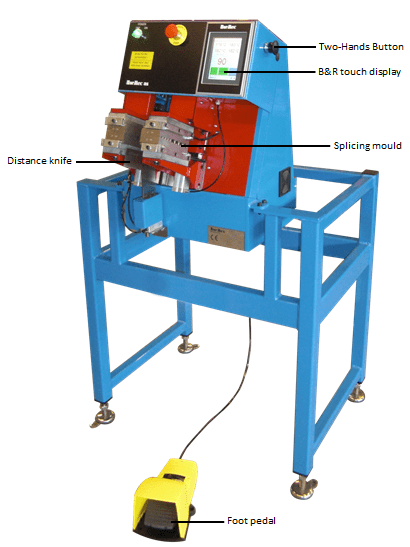

The Standard press 110-00-165-BR is our newest and most advanced model. This press is a development of our reliable Standard Press 101-00-80, which we have produced for over 20 years.

The new model has several new and smart solutions and improvements in the construction to handle tools up to 175mm.

We know time is money therefore have we designed the press with usability as top priority. The operator will in matter of minutes understand the basic features on the machine.

All presses are equipped with a production log where all production data is stored for 12 months. With use of this information you can make your production even more effective. The production data can directly be downloaded to a USB-Stick.

The user can easily set-up all settings on the machine directly in the Interface. One of the new features is password protection of the machine with up to 5 user-levels; each user level with different access level.

Another feature we have developed to make our machines as effective as possible is the opportunity to preheat the machine before the operator gets to work. The operator will find the machine ready for production at the time he arrives.

If any problems should occur it`s easy troubleshooting directly from the control panel. If you should not be able to solve the problem by yourselves, connect the machine to internet and we can connect and find out what the problem is.

The NorMec Standard press is delivered in accordance with the CE Directive.

NorMec is a full-service company and we assist you all the way from receiving a drawing of the profile until we have achieved the perfect splice.