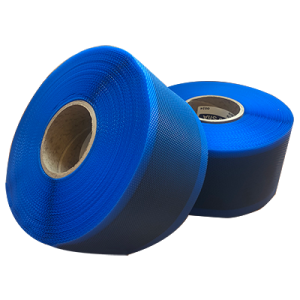

Splicing film

The balance between strength and speed is unbeatable. According to customer feedback, production efficiency increases, failure rates drop, and strength improves.

Purchase our most common dimension in our Online Store.

More than 30 years of experience

NorMec is a Norwegian family-owned company and the marked leader in development and production of equipment for hot vulcanization and infrared splicing solutions for 30 years.

NorMec is the developer of the hot film vulcanizing technique. The technique was developed by our engineer and main shareholder Jan Leif Slettemoen in the being of the 1980`s.

The technique was groundbreaking, when it was introduced for the market in 1989. The method replaced more traditional techniques such as gluing. The principle of the new technique was use of un-vulcanized rubber, splicing dies for the profiles cross-section and user-friendly machines.

The new technique was referred in the industry as the “NorMec Method” and still is.

To continuing to be the marked leader we constantly push the limits to develop new machines and techniques to offer our customers.

News:

Semi-Automatic Rotating cutter 401-07-150

Our rotating cutter are designed to produce a perfect cutting result, angled or straight. The [...]

Cutting Machine 401-04-100

Our user-friendly guillotine cutter comes equipped with an end stop, profile clamping, and a 2-hand [...]

Summer holiday 10th – 30th of July 2023

During the weeks of 28-30, the production at the NorMec is closed. The office will [...]