The new model has several new and smart solutions and improved construction to handle tools up to 150 mm.

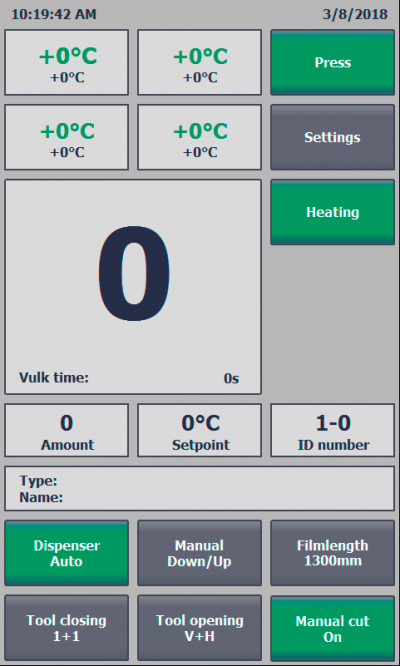

We know time is money therefore have we designed the press with usability as top priority. The operator will in matter of minutes understand all the basic features on the machine. With just a click the operator can set temperature, time or load an already stored program for the specified profile.

The user can easily set-up all settings on the machine directly in the Interface. One of the new features is password protection of the machine and new help function for the operator and maintenance personnel.

If any problems should occur, it`s easy troubleshooting directly from the control panel.

The newest optional feature is installation of VPN (Virtual Private Network). With the VPN our technical engineers can connect directly too your machine for troubleshooting or upgrading of software.

Operation procedure:

The NorMec presses is featured with the 3 different operation procedures to make the press flexible to splice a large range of profiles. Changing between the 3 procedures is made with just a click on the touch-display.

All of NorMec’s splicing presses is equipped with the ”gap”-program. The ”gap”-program involves closing the tools in the press with two-hands buttons and once released again the tool opens approximately 2 mm and the operator have both hands free to insert the profiles into the tool. After this is done the profiles is locked in the tool by pushing the foot-pedal.

All NorMec splicing presses has functions that give the operator opportunity to close one and one side off the tools. This allows the operator to use both hands to hold multiple profiles when he wants to splice for instance 6 profiles in the same operation.

It is also possible to close the tools and lock the profiles in the tool in the outer position, this make it possible to cut the profile directly in the tool. This makes it easy to achieve good angle splices when dealing with difficult profiles.