Precision above all

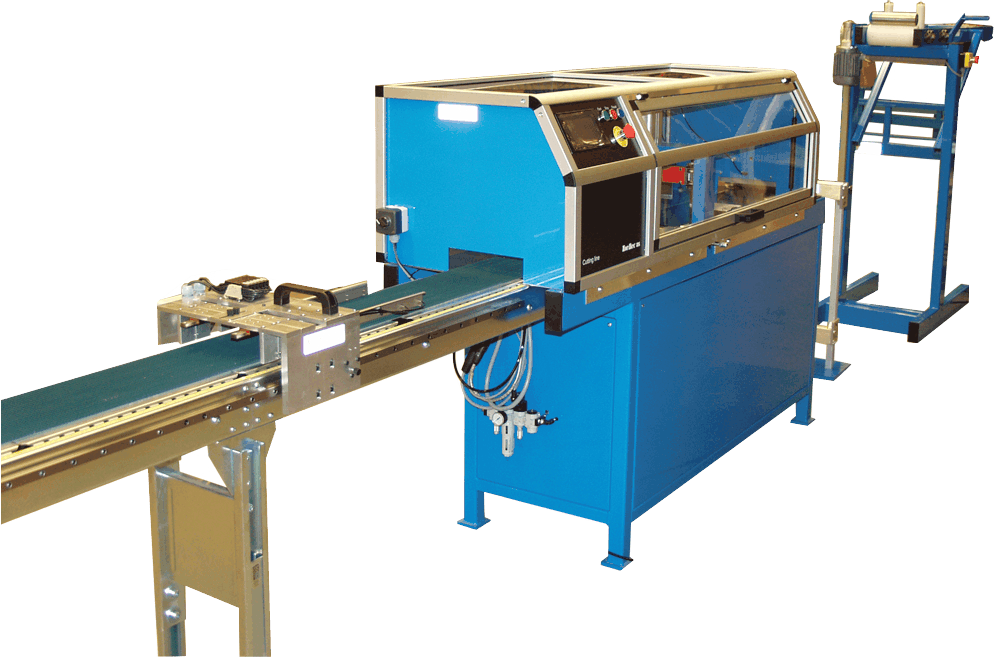

Our fully automated guillotine cutter has been developed with precision in mind. The use of photocells to measure correct lengths as well as after checks of the length mean that the machine always produces lengths that are within the given tolerance.

At the front of the machine there is space for a loop that ensures the profile is fed correctly without any kind of tension on the profile. The guillotine cutter can be installed in either an extruder line or collect the profile from a box/reel.

As with all of our other machines ease of use is important and our cutter machines are also available with touch display for straightforward control of cut lengths, speeds, number of cuts and not least, control of preprogrammed recipes.

Our automated cutting machines can be supplied with a variety of optional extras, such as kick-off function on the conveyor belt, lift for feeding an overhead conveyor or other additional equipment to meet the customer’s needs.

All our machines are certified to the CE standard.

NorMec is a full-service company and we assist you all the way from receiving a drawing of the profile until we have achieved the perfect splice.